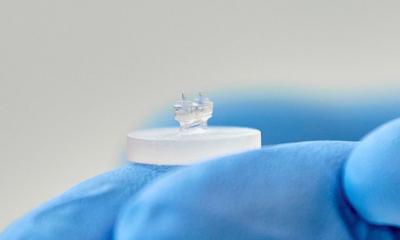

Image source: Mayo Clinic

News • Dermatology prototype

3D skin bioprinting shows potential for eczema treatment

Mayo Clinic has developed its first 3D prototype of human skin bioprinted to model inflammatory skin disease. 3D bioprinting is a technology that mixes bioinks with living cells to print natural tissue-like structures in three dimensions.

This new technology provides the most human-like skin model for studying inflammatory conditions such as atopic dermatitis — more commonly known as eczema — a chronic inflammatory skin condition that causes dry, itchy and inflamed skin. The 3D bioprinting skin procedure, applications and limitations are described in a review article in Regenerative Biomaterials.

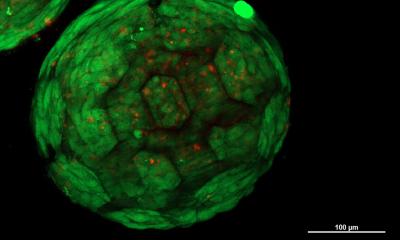

Image source: Mayo Clinic

"3D bioprinting is a burgeoning field in tissue engineering and regenerative medicine that has the potential to transform clinical and laboratory practice. In this article, we discuss the process of 3D bioprinting skin, including cell selection, scaffold selection, and advantages and disadvantages of certain skin bioinks," says Saranya Wyles, M.D., Ph.D., a dermatologist and senior author of the article. "This 3D model more accurately recreates disease, creates surgical grafts and provides the ability to test new therapies."

Eczema affects 30 million Americans, mostly children and adolescents, according to the National Institutes of Health. This painful condition causes dry, itchy skin that can trigger an immune response can in turn cause inflamed skin. Eczema can weaken the skin's ability to retain moisture and protect against bacterial, viral or fungal infections. People with this disease are often at risk of conditions such as asthma and food allergies. The few treatments that exist can ease the symptoms but are not a cure.

Research to increase understanding of eczema and advance new therapies for this condition has been limited by a lack of preclinical models that accurately simulate human disease. "That's where 3D bioprinting brings new options. It can create human equivalents that are truer and more representative of the disease, unlike the animal models we have worked with in the past," says Dr. Wyles. "Inflammatory skin diseases and rare diseases can be modeled (through bioprinting) for better understanding of the underlying pathology and drug testing and how that might affect the patient."

Our system allows us to use up to six different cell types to model and recreate human skin tissue

Saranya Wyles

Dr. Wyles' team, including collaborator Alexander Revzin, Ph.D., hopes to replicate inflammatory skin conditions using cells of people with eczema to 3D bioprint skin. The research team will test topical and injectable regenerative therapies such as exosome technology on bioprinted skin in hopes of identifying new therapies. Exosomes are cell-free substances that act like a delivery service, moving cargo from one cell to another with instructions for targeting exact tissues that need repair. Dr. Wyles’ research is supported by Mayo Clinic's Center for Regenerative Biotherapeutics and funded by the Skoll Foundation. Her work advances the center's objective of delivering new cellular therapies for complex conditions with few therapeutic options.

Skin is the body's largest organ, and it regenerates monthly. The 3D bioprinting model seeks to replicate the complexity of skin layers, but has yet to incorporate the sweat glands, blood vessels, skin follicles and nerves found in native human tissue. "The 3D bioprinter uses human cells as inks called bioinks, which act similar to ink from a printer ink cartridge. We can print the skin from cells of patients with atopic dermatitis or eczema," says Dr. Wyles. "Our system allows us to use up to six different cell types to model and recreate human skin tissue."

The research team uses many types of cells including melanocytes, which form skin pigment; keratinocytes, which allow for skin renewal; and fibroblasts, which form a connective tissue. These cells are printed in layers that stratify and mature into full layers of skin. "The printing process is sort of like creating layers of a tiered cake with different cell types,” says Dr. Wyles. “You start at the bottom (the dermis), then you add the next layer (the epidermis), and the scaffold material acts as the frosting to connect the layers. The printed skin is put into an incubator where the cells can communicate with each other, expand and form bioprinted skin."

Research using 3D bioprinted skin goes beyond inflammatory disease. Dr. Wyles also uses the prototype 3D models to better understand, on a molecular level, the role of senescent cells in age-related skin conditions. Also called zombie cells, senescent cells no longer divide and multiply, and therefore are not able to heal and repair tissue. Her goal is to better develop new therapies to address skin aging.

More research is needed to bioprint an exact replica of human skin with atopic dermatitis. Future studies will explore 3D bioprinting of full skin thickness with an emphasis on attaining the full features of patient-specific skin.

Source: Mayo Clinic

26.07.2023